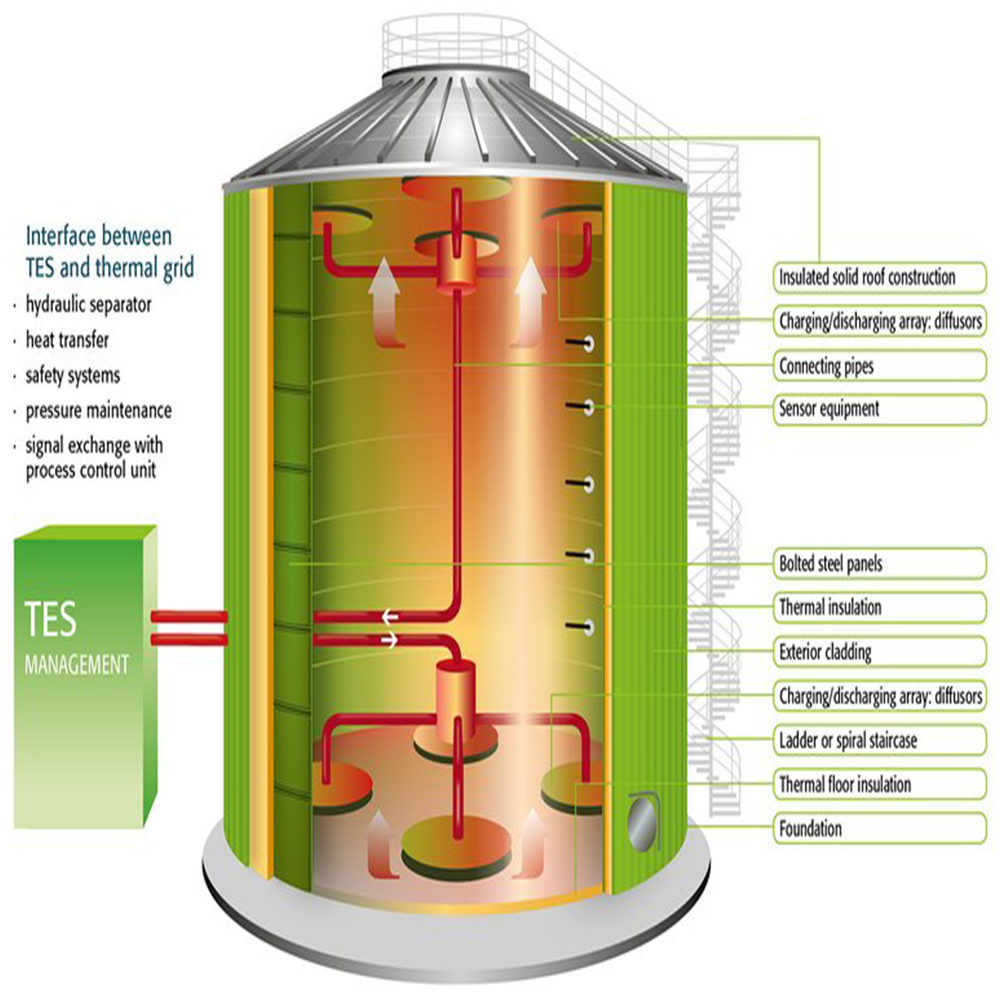

Product description

API Energy Thermal Energy Storage (TES) tank allows the storage of chilled water produced during off-peak periods. A TES tank reduces the operational cost and the required capacity of cooling plants, increasing the efficiency of the cooling plant and reducing the capital cost. Thermal Energy Storage (TES) tank is a widely proven technology that collects excess process thermal energy to be used during load peak hours. By producing chilled water in the evening and using it during daily peak hours there are several advantages. API Energy thermal storage tanks provide a tailor-made solution in the fields of refrigeration, cooling and heating.

The TES technology, in District Energy plants, allows for a reduction in operation costs and refrigerant plant capacity requirements. API Energy provides and designs Ice storage, Stratified water storage and Salt storage. API Energy with collaboration has developed several engineered solutions for Oil & Gas, Pharmaceutical, Food& Beverage Markets.

API Energy provide tank and also turnkey heat/cold storage system

Our energy storage technology allows for the substitution of chillers/ boilers on standby for peak-load operation in both district heating and district cooling grids. Additionally, low off-peak energy tariffs can be used for heat and cold energy generation. Thermal storage systems are a key component for successful participation in the energy market for balancing electricity.

Our services in the field of Thermal Energy Storage system:

- Design calculations and engineering for thermal energy storage systems

- Installation of the storage tanks and the charging and discharging arrays

- Design and installation of the stratification and storage management

Energy Management

API Energy combines the best available sensor equipment with an optimised process control for charging and discharging cycles and ensures that not a single kilowatt hour of stored energy is lost. We can integrate the entire TES system into any existing infrastructure or new projects and manage all battery limits for you.

Function of API Energy Thermal Storage Systems

Stratified thermal energy storage systems made by API Energy are a key technology for optimised energy utilisation. By integrating thermal storage systems into district heating and cooling grids, our customers can optimise production processes, peak load energy supply and overall grid stability. Thermal storage systems allow for efficient intermediate storage of heat from combined heat and power plants and from solar heating for later use.

API Energy Thermal Energy Storage (TES) applications

Industrial processes, i.e Utilisation of waste heat from power plants and industrial parks.

In larger public and private infrastructure projects i.e Thermal storage for district heating / Cooling , close to the producer or located decentrally near consumers.

TEs as buffer for decentralized thermal grids with solar collectors, for biomass power plants and for biogas plants connected to district heating.

In CHP plants (e.g. biogas plants).

Power-to-Heat: storage of excess electricity in form of heat.

API Energy Thermal Storage Systems Advantages

Air conditioning in industrial complexes, public buildings (e.g. hospitals, university campuses) and in large infrastructure projects (e.g. airports, malls, housing).

Cold energy for processes in the food industry, for cold storage units and greenhouses.

Provision of cooling reserves for cooling of gas turbines in large power plants.

Reduction of installed boiler / Chiller capacity and of heat producers on standby for peak operation.

Operation costs savings from reduced maintenance of boiler / Chiller installations.

Cost savings from operation of heat / Chiller units producers at maximum efficiency.

Separation of heat producer and consumer allows for economical electricity generation in CHP.

Power plants even in the temporary absence of a demand for heat.

Thermal energy availability even during downtimes of generators / CHP units.

Optimal thermal stratification.

Custom design of each API Energy Thermal Storage Systems system as opposed to adaptation of standardised products to the customer’s requirements.

TES as a pressureless vessel does not require regular inspections as opposed to pressure vessels.

Very short assembly times and consistent high quality anywhere in the world.

Flexible application as a small TES (from 50 m³) with a grid connection by heat exchanger or as Industrial large scale TES (up to 5,000 m³) with direct connection to the pressurised.

High short-term thermal output capacity with minimal energy loss.