ROTARY KILN

ROTARY KILN

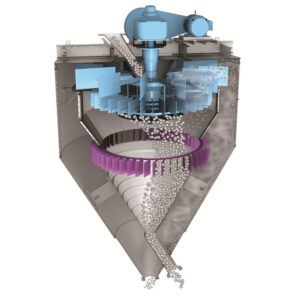

API EnergyTM Rotary Kiln is a rotating cylindrical vessel which is used for drying, calcination and sintering in a continuous process with the use of hot gases. The hot gases may be generated in an external furnace or by a flame inside the kiln. Our cement rotary kiln and sponge iron rotary kiln has been developed for performing drying, calcination and sintering work in a continuous process. Widely used for cement, pet coke calcination, sponge iron and other materials, it uses hot gases for the operation. Integrated with variable speed drive, process automation and instrumentation, this kiln ensures optimum operational control. In addition to technology, its design features better inlet and outlet sealing to ensure minimum false air entry.

API EnergyTM Rotary KilnFeatures :

- Better inlet and outlet sealing to ensure minimum false air entry.

- Hydraulic thruster provides control to the Kiln axial movement.

- Three support roller stations are provided for better distribution of forces on shell.

- Ensures optimal safety with regard to material elasticity at operating temperature.

- Throat adjuster is provided to optimize Kiln / Calciner fuel.